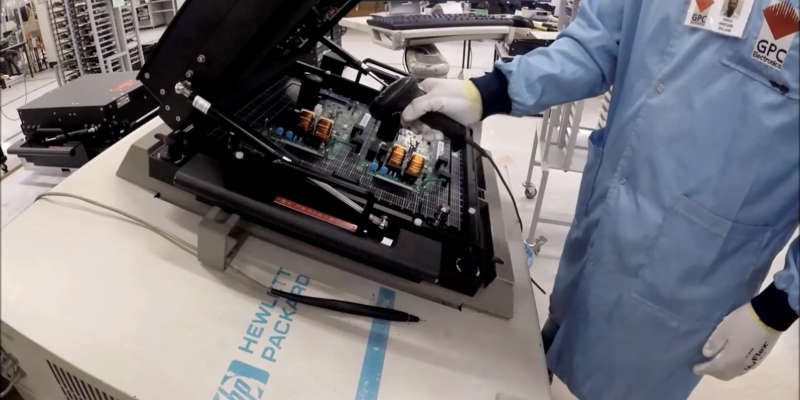

We make it happen

GPC Electronics is your manufacturing partner from the moment your business idea is born through to your final high-quality product.

sector

Automotive

Battery Management Systems, Electrical Systems, EV Chargers, and Electronic Control Units are all vital parts of a modern vehicle. We have many years of experience in building high quality electronic modules for the global automotive industry.

sector

Commercial

From air purifiers to automated farming and drinking water, GPC delivers high quality electronics to some of the world's leading brands. Our team has long experience in manufacturing and testing the most complex systems, including RF & Digital Communications, Industrial Controls and Internet of Things (IoT) Devices.

sector

Medical

Medical devices are becoming increasingly complex, miniaturised and integrated in our daily lives. We supply electronic modules and total solutions to the medical industry worldwide.

sector

Aerospace

The aerospace industry is developing into un-manned, optionally manned and manned aircraft. The common denominator is the extensive use of high-quality avionics to ensure mission success. GPC supplies leading aerospace companies worldwide.

sector

Defence

As Australia's leading electronics manufacturing services partner for Defence, we supply to Navy, Army and Air Force. Our organisation holds an AS9100D accreditation and is a DISP member. We have long experience in manufacturing advanced RF and Communication solutions and advanced ruggedised electronics.

sector

Space

Space is vital to all aspects of our modern life, from banking to communication and navigation. GPC has flight heritage and delivers components, modules and systems to the Space industry for LEO, MEO and beyond.

Services

Since 1985, GPC Electronics’ complete electronics manufacturing services have provided some of the globe’s most iconic companies as well as new-to-market start-ups with reliable professional services and capabilities.

.webp)